Futuristic Robots For A Futuristic Work Environment

Technology has made sweeping advancements in this age, and it will continue to do so in the future. It is especially true in the case of robots. Robots are getting out of their usual roles from warehouses and factories to occupy offices, spaces, retail shops, banks, and more. Such futuristic next-generation robots are called collaborative or cobots and commercial or service robots. Cobots work in collaboration with human workers to achieve a task. Service robots perform automated tasks guided by the algorithm, and a few examples are drones, guided vehicles, medical robots, field robots, and more.

The traditional industrial robots are the biggest market in the robotics industry. Robot manufacturers raked about $12 billion in sales of industrial robots. Cobots and service robots had a small market share. But, the numbers are improving year on year. Next-generation robots are slowly infiltrating the business arena. They are now changing business and resource plans. These robots are now gaining more acceptance in the field of hospitality, food and beverage, retail, health care, banking, and even homes.

Business strategists and leaders are now showing definite interest in considering robots as a resource that can be used to enhance customer satisfaction, increase operational efficiency, and bring in more business. These next-generation robots are projected to grow up to 22% by 2025, accounting for two-thirds of robot sales. Significant companies like Toyota are investing heavily in robotics. Plans are underway to make robot assistants that can perform tasks such as caring for the elderly.

Different Applications of Collaborative Robots

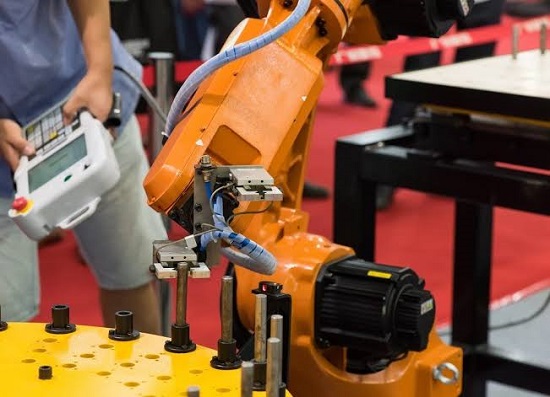

Advancement in both software and hardware has made it easy to build robots with powerful capabilities. It has become relatively easier to train and configure industrial robots with sophisticated behavior, powerful vision systems, and apply the robotic positioning system. Robots have become more flexible with improved ability and application of artificial Intelligence. Natural language processing, speech recognition, and computer vision has to give robots a sophisticated capability to interact with humans. Training robots by giving examples like the cloud-connected robots use reinforced learning to learn tasks has minimized personal training.

Increased human interactions and collaboration have given way to several applications for robotics. Industrial robots play a significant role in the manufacturing industries. They perform routine tasks that are at high risk for normal humans. Tasks such as loading, unloading, testing, fabricating, assembly, and packaging are the usual roles of robots in any industry.

Cobots are used for more collaborative human interaction tasks. It is now increasingly used in health care for surgical assistance, sanitation, rehabilitation diagnostics, and more. Drones are used for inventory maintenance, surveillance, inspection, and monitoring of infrastructure, construction, and agriculture. Navigational and interactive skills of robots are finding use in customer services, meal assembly, and security surveillance. Check Out the recent article for your better reference about collaborative robots.

Impact Of Robots In Businesses

The evolution of robots has been benefiting businesses and industries. Now executives can overcome labor shortages by using innovative robots in factories, warehouses, and offices. Increased automation reduces operational costs and risks. It may seem expensive to install robots in the first go. But, as it becomes operational and the capabilities tested, robots can invariably increase efficiency and product quality. It reduces the need for human labor.

There is a growing demand for robots that has culminated in decreasing selling prices. The selling price of industrial robots has dropped by 4 percent, and Cobots have declined by 3 percent. The cost of different types of service robots has declined by 2 to 9 percent. Financially, this decline in price has a good impact on businesses. It is now visible to install tidbits in factories, restaurants, hospitals, and farms. Aging workers can focus on less taxing work as cobots deal with physically daunting tasks.

Robotic technology and its applications have paved the way for restoring manufacturing facilities. These days, companies are looking to have factories close to their research and office center or large markets. Robots have reduced the turnaround time for producing quality products. This has increased responsiveness to demand. Robots have become smarter, capable, and more affordable. The use of robots is growing in all fields, and this has brought about a positive change in business operations.